BORING EQUIPMENT FOR TUNNELING APPLICATIONS

We manufacture custom heavy equipment for utilizing exisiting auger boring equipment for tunneling and pipe-jacking applications. Heavy equipment that can be used for tunnel applications includes the following:

- Adapter Assemblies for Tunneling and Pipe-Jacking Applications

- "Line-up" Assemblies for Guided Boring Applications

In addition, we offer the following equipment used in standard tunneling applications for use with a customers current auger boring equipmet:

- Tunneling and Pipe-Jacking Shields

- Excavators

- Conveyors

- Hydraulic Power Units (HPUs)

- Muck Cart and Track

- Underground Lubricant Systems

- Intermediate Jacking Stations

- Backstops (Thrust Walls).

To obtain more information on how our boring equipment can help you achieve your tunneling objectives, please contact us.

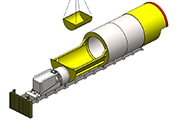

ADAPTER ASSEMBLIES

At Tenbusch, Inc., we design and manufacture tunneling equipment that can be used with your existing boring equipment to complete tunneling applications. We can provide pipe adapters specifically suited to the make and model of the your boring machine and compatible with the pipe products to be installed, including:

- Steel casing,

- Re-inforced concrete pipe,

- Pre-cast box-culverts.

Systems for adapting auger boring machines and equipment to perform tunneling applications typically include some or all of the following equipment:

- Tunnel shields,

- Excavators,

- Conveyors,

- Adapters for machine-to-pipe or machine-to-box-culvert,

- Spoil removal equipment,

- Backstops.

Please review our adapter assemblies and custom heavy equipment brochure:

LINE-UP ASSEMBLIES FOR GUIDED BORING

The Line-Up Bearing Assembly is a tool used in Guided Boring / Pilot Tube Micro Tunneling. It bolts onto a large diameter cutting head, allowing the head and larger casing to follow precisely the line and grade of the previous installed smaller casing.

By using a bearing, the front of the assembly stays stationary, as the large head rotates.

Aspects of the Tenbusch Line-Up Bearing Assembly:

- Rotary Bearing – Makes it possible for part of the assembly to remain stationary and mated inside the smaller casing while the larger cutting head rotates. This ensures the larger bore follows the line and grade of the smaller casing.

- Seal – keeps debris and abrasives out of the bearing ensures proper mating and function of the bearing, crucial to keeping the larger diameter head and casing on precise line and grade.

- Bolt On Assembly – design allows for minimal alteration of the existing large cutting head. Head can be used for intended use and cutting with minimal alteration after job is complete.

Line-Up Bearing Assemblies are custom built to the specifications of your job and larger cutting head. Low lead times – our products are designed and manufactured in Lewisville, TX, USA.

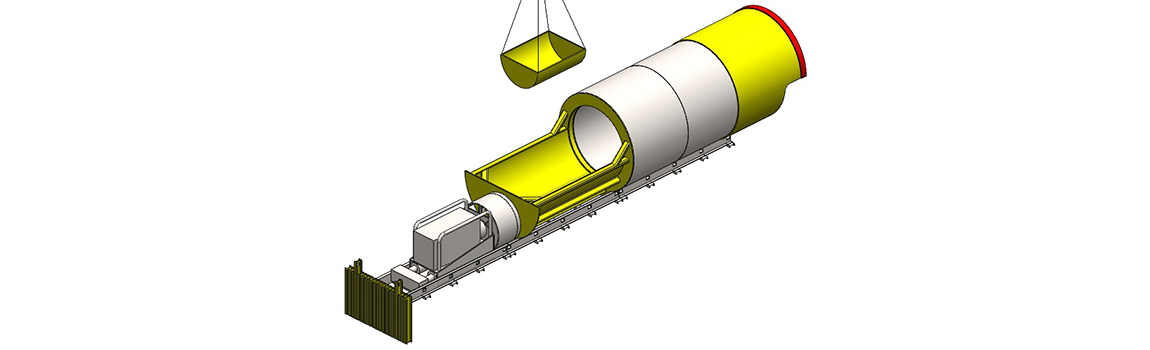

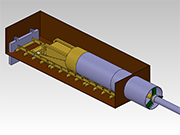

MUCK CART AND TRACK

Tenbusch Inc. designs and manufactures custom spoil removal equipment for conventional pipe-jacking and liner plate tunneling applications. Tenbusch track is designed with the following features:

- Designed to be easily bolted together in the tunnel,

- Customer specified track gauge and track lengths,

- Sized for maximum strength and rigidity,

- Kept as light as possible to make it easy for the workers to install.

The spoil bowl is separate from its cart so as to be easily removed and dumped. The bowl is designed to automatically dump when lifted by the appropriate lift point. Quality design, function, and manufacture.

More details are presented in the following brochure we have prepared: