TENBUSCH UNDERGROUND EQUIPMENT

Need heavy equipment that is not "on the shelf" or needs to be specific for your application?

At Tenbusch Inc., we design and manufacture custom heavy equipment for installing underground pipe and utilities using tunneling, jacking, or sliplining processes. Its what we do. Underground construction equipment includes, but is not limited to, the following:

- Tunnel Boring Machines (TBMs)

- Tunneling and Pipe-Jacking Systems - For Both Liner Plate and Pipe-Jacking Applications

- Box-Culvert Jacking Systems

- Sliplining Systems

- Pipe Carriers

- Hydraulic Power Units (HPUs)

- Lubricant Systems

- Backstops

- Custom Equipment for Infrastructure Contractors

- Custom Boring Equipment for Tunneling Applications

- TIM™ Systems

To obtain more information on how our underground equipment can help you achieve your objectives, please contact us.

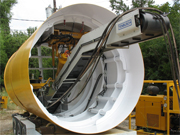

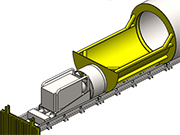

TUNNEL BORING MACHINES (TBM's)

We manufacture tunnel boring machines (TBM's):

- Custom designed and specifically tailored to the customer's needs and applications,

- Manufactured for both liner plate and pipe-jacking applications,

- Removable hydraulic power unit (HPU) available as an option,

- Delivered as stand alone unit or part of a tunneling system package.

We manufacture the auxiliary equipment needed for a complete tunnel boring system - conveyors, muck carts and track, underground lubricant systems, thrust walls, and external hydraulic power units (HPUs).

TUNNELING AND PIPE-JACKING SYSTEMS

We manufacture tunnel and pipe-jacking systems:

- Custom designed specifically for the customer's application,

- For both liner plate and pipe-jacking applications,

- Available as stand alone components, or delivered as a complete system.

We manufacture all the auxiliary equipment needed for a complete tunnel or pipe-jacking system:

- Excavators

- Conveyors

- Hydraulic power units (HPUs)

- Muck cart and track

- Underground lubricant systems

- Backstops (thrust walls).

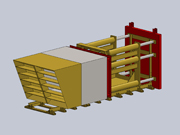

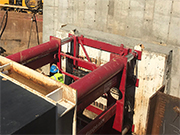

BOX-CULVERT JACKING SYSTEMS

We manufacture complete box-culvert jacking systems for installing various sizes of box-culvert tunnels:

- Specifically designed for jacking box-culverts tunnels -

- Facilitates an easy setup,

- Provides for efficient operation,

- Supplies required thrust,

- Interchangeable push adapters allow a single machine to install a range of box-culvert sizes,

- Provides control and monitoring of jacking forces,

- All equipment is hydraulically powered.

We manufacture the auxiliary equipment needed for a complete box-culvert jacking system - shields, excavators, conveyors, muck carts and track, hydraulic power units (HPUs), underground lubrication systems, and thrust walls.

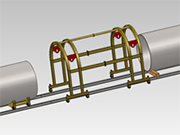

SLIPLINING SYSTEMS

We manufacture heavy duty sliplining systems (for installation of pipe into an existing, larger diameter, pipe):

- Efficient design minimizes the required insertion pit size,

- Modular design allows a range pipeline diameters to be installed with a single base machine,

- Available in single direction or dual push direction units.

Dual push direction units allow pipe to be pushed during both extension and retraction of the machine. This maximizes installation efficiency and enhances productivity.

We manufacture all the auxiliary equipment needed for a complete sliplining system - pipe shields, pipe mandrels, pipe adapters, and hydraulic power units (HPUs).

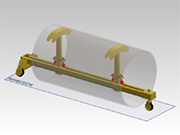

PIPE CARRIERS

We manufacture heavy duty pipe carriers for installing pipelines in large existing lines or tunnels.

In certain applications, the best means of installing a large diameter pipeline is to carry in and install the pipeline piece by piece. These cases typically include installation of the pipeline into an existing tunnel or pipeline where there is sufficient space available for assembly operations. Tenbusch Inc. designs and fabricates pipe carriers for large diameter pipe installation

When selecting a pipe carrier many factors and application details come into play. We have prepared a buyers guide to help you:

![]() Tenbusch Pipe Carrier Buyer's Guide

Tenbusch Pipe Carrier Buyer's Guide

Use this a resource for your research into pipe carriers for your applications.

HYDRAULIC POWER UNITS (HPU's)

We manufacture heavy duty hydraulic power units (HPUs) for underground construction applications. Our hydraulic power units are designed to provide continuous and reliable power to your equipment. Typical features of our HPU's include:

- Robust protective frame for rough job environments,

- Electric motor or combustion engine power source,

- Multiple pumps for main, auxiliary, and filtration circuits,

- Controls to match your requirements and appropriate monitoring equipment and gauges,

- High capacity hydraulic reservoirs matched to underground equipment applications.

You can choose from preconfigured HPU models or custom designs.

LUBRICANT SYSTEMS

We design and manufacture systems for mixing and pumping underground lubricants such as bentonite and/or polymer. Lubricants are required in underground construction applications to reduce friction and lower jacking forces for pipeline and box-culverts. Tenbusch lubricant systems are very efficient and effective - the mixing and pumping processes have been optimized for the specific conditions encountered in underground construction:

- High pressure fluid circuit for long transmission lines and to penetrate annular spaces surrounding pipe,

- Low pressure fluid circuit for mixing and transport,

- Controls to match flows to work requirements.

- High-capacity, multiple, reservoirs appropriate for underground applications,

- Hydraulically powered.

You can choose from pre-configured lubricant system models or custom designs. Integral power source units are available.

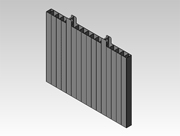

BACKSTOPS (THRUST-WALLS)

We design and manufacture portable backstops (thrust walls) to stabilize and improve the following underground construction operations:

- Tunnel boring machines (TBM),

- Tunneling and pipe-jacking,

- Sliplining,

- Boring,

- Trenchless pipe installation.

Backstops provide a large, portable, and easily transported mass which distributes thrust and minimizes deflection and drift of heavy equipment in underground applications.

CUSTOM EQUIPMENT FOR INFRASTRUCTURE CONTRACTORS

Tenbusch Inc. designs and fabricates custom equipment for infrastructure contractors. Typical equipment manufactured for infrastructure applications includes platforms and staging trailers for pipe installation operations.

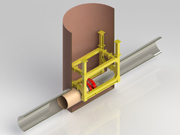

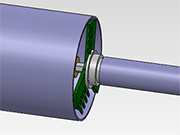

CUSTOM BORING EQUIPMENT FOR TUNNELING APPLICATIONS

Tenbusch, Inc. designs and manufactures tunneling equipment that can be used with your existing boring equipment to complete tunneling applications. This equipment includes:

- Adapters for mating your existing boring machine to any size casing,

- Guided boring tools such as a "line-up" bearing assembly.

We can provide pipe adapters specifically suited to the make and model of the your boring machine and compatible with the pipe products to be installed. Additionally, our Line-Up Bearing Assembly is a tool used for Guided Boring / Pilot Tube Micro Tunneling. It bolts onto a large diameter cutting head, allowing the head and larger casing to follow precisely the line and grade of the previous installed smaller casing.

TIM™ SYSTEMS

Tenbusch Inc. has developed the Tenbusch Insertion Method (TIM™) and equipment for trenchless pipe replacement. The TIM™ System allows local contractors to replace ailing underground infrastructure for both municipal and industrial applications. The TIM™ system is a unique pipe replacement (pipe bursting) method that jacks new rigid pipe in place of the existing deteriorated pipe.